Revolutionary High-production

Abrasive Blasting Technology

GLOBAL ENGINEERING

- TRUSTED SOLUTIONS -

ALBA AIR SYSTEMS

Alba Air Systems CC was established in 2004, and is the authorized South African distributor for Clemco International GmbH, the worldwide recognised manufacturer and supplier of Clemco abrasive blasting equipment.

Clemco was founded in the USA in 1949 with the joint goals of providing revolutionary high-production abrasive blasting technology and of setting a new standard for product quality, maximum efficiency, operator safety and comfort.

Based in Ballito, KZN, we endeavour to have on stock usual types and sizes of blast machines, related spares and accessories.

Contact us to discuss your requirements or ask any questions.

Clemco products conform, where necessary, to European and USA safety standards.

CE Approved Pressure Blast Machines : capacity 60ltr, 100ltr and 200ltr

Blasting Hoses : I.D. 13mm, 19mm, 25mm and 32mm

Nozzles : All sizes available, liner material: Tungsten Carbide, Silicon Carbide and Boron Carbide (please enquire on suitability for your specific needs)

Hose Couplings, Nozzle Holders, Rubber Seals : All sizes available

Suction Blast Systems: Power Injection Gun, SG300 Suction Gun, BNP Cabinet Gun, etc.

Dust Free Portable Blast Systems: Pressure Blast and Suction Blast, e.g. Eductomatic

Internal Pipe Blast Tools: e.g. Hollo-Blast, Spin Blast

Personal Protective Equipment (PPE) : CE Approved Air-fed Blast Helmets, e.g. Apollo 100 and Apollo 600, Heavy Duty Blast Suits, Breathing Air Filters, etc.

Blast Cabinets: Pressure Blast and Suction Blast, full range of capacities available to suit your needs, from light duty small work pieces to heavy duty large work pieces

We deliver country wide, using dedicated courier service. Please click here to browse individual information on any of Clemco products.

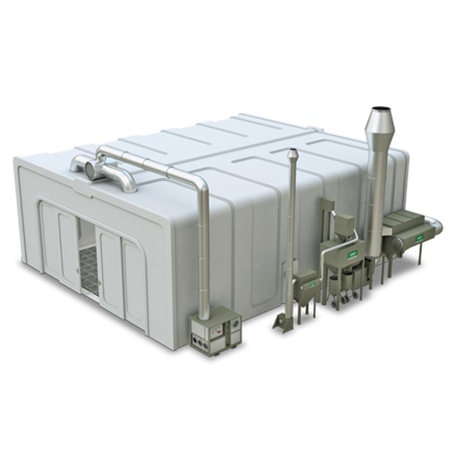

In addition, Munkebo A/S is a wholly owned subsidiary of Clemco International GmbH, and they are a well established manufacturer of full blast room facilities. Please enquire here for product information, or please make an initial enquiry here.

.

Pressure Blast Systems

The blast machine, colloquially known as sandblasting machine, is the heart of the pressure blasting system. Attention to the proper configuration and compatibility of the machine’s components is crucial and ensures maximum blasting efficiency. Thanks to Clemco’s wealth of experience and commitment to innovation, Clemco products deliver high levels of reliability, longevity, and safety in abrasive blasting.

Operator Protection- PPE

The first priority is operator safety with proper sandblasting clothing. Clemco CE-approved accessories protect the blast operator from excessive heat, cold, dust and noise; all irritants and safety risks are addressed. Protection in tandem with comfort is the focus of Clemco safety products, and when Clemco equipment is used with the proper accessories, the blaster can safely and comfortably concentrate on his work, achieving the highest level of productivity.

Blast Cabinets

The blast machine, colloquially known as sandblasting machine, is the heart of the pressure blasting system. Attention to the proper configuration and compatibility of the machine’s components is crucial and ensures maximum blasting efficiency. Thanks to Clemco’s wealth of experience and commitment to innovation, Clemco products deliver high levels of reliability, longevity, and safety in abrasive blasting.

Dust Control

Clemco dust control systems with closed-circuit can be used to blast virtually anywhere. No elaborate containment or housing is needed. A closed-circuit blast system emits no abrasive particulate or dust and consumes a minimum amount of energy while maintaining the blast stream in a contained, safe pattern.

Injector Blasting

The first priority is operator safety with proper sandblasting clothing. Clemco CE-approved accessories protect the blast operator from excessive heat, cold, dust and noise; all irritants and safety risks are addressed. Protection in tandem with comfort is the focus of Clemco safety products, and when Clemco equipment is used with the proper accessories, the blaster can safely and comfortably concentrate on his work, achieving the highest level of productivity.

Inner Pipe Blasting

Pipe interiors are awkward to access, while demanding a high degree of surface cleanliness prior to coating. Clemco‘s pipe-blast tools combine total coverage of pipe interiors with precise and efficient performance. Clemco has devoted years to refining the technology of inner pipe blasting and draws on this experience to deliver the highest-performing pipe tools available.

Automation Blasting

Automated cabinet blasting offers distinct advantages for the processing of large-volume production and ensures accurate and consistently repeatable results. In Clemco’s test labs, careful sample evaluation, planning and testing form the basis for the design of a specific automated system. Clemco automated cabinets are designed to perform at peak efficiency while fitting seamlessly into a customer’s production line.

Stationary & Mobile Systems

Custom-designed blast rooms are the optimal solution for large workpieces. Clemco staff methodically works with each and every customer to determine their exact blast room equipment requirements. Using this data, Clemco engineers design a blast room tailored to every specific of the job, taking into account each consideration of safety, efficiency and performance. Clemco quality blast rooms set the industry standard worldwide, and every detail reflects this commitment.

Non-agressive Blast Systems

For aerospace and other industries, surface treatment has to fulfill the highest safety standards. Clemco systems have proven to be an economic, effective, and versatile solution – particularly in this specific area. Specialized lightweight media is used for stripping, cleaning, and deburring delicate metals and composites gently, precisely, and quickly, and quickly, safely for the operator and the environment.

Special Blast Cabinets

Special blast solutions for individual customer needs.

To view the full product offering and other information, click/tap to download the Clemco Internation company profile pdf:

.

CONTACT DETAILS

Details

Form